The Ursa Major

Standard

Quality to perform. Additive manufacturing to scale. Systems built for today’s fight and tomorrow’s threats.

Quality

Certified Precision. Operational Excellence.

At Ursa Major, quality isn’t a box to check—it’s a strategic advantage. As an AS9100D-certified manufacturer, we uphold the highest aerospace standards across our operation, from design through delivery. Every propulsion and defense system we build reflects our commitment to mission assurance, customer alignment, and continuous improvement.

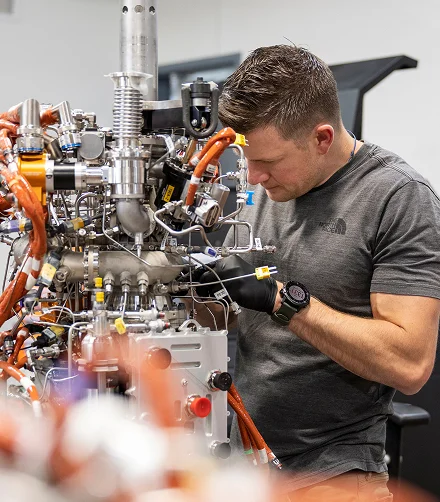

We bring the same engineering discipline to our quality systems as we do to our product lines. We apply advanced manufacturing techniques and integrate real-time quality validation into every step of the process. With tightly connected design, test, and production teams, we embed quality from day one to deliver American-made systems with the performance our customers demand and the warfighter depends on.

DESIGN

We design for outcomes. Our engineers leverage advanced modeling, iterative prototyping, and lessons from flight to push the boundaries of what’s possible.

FABRICATE

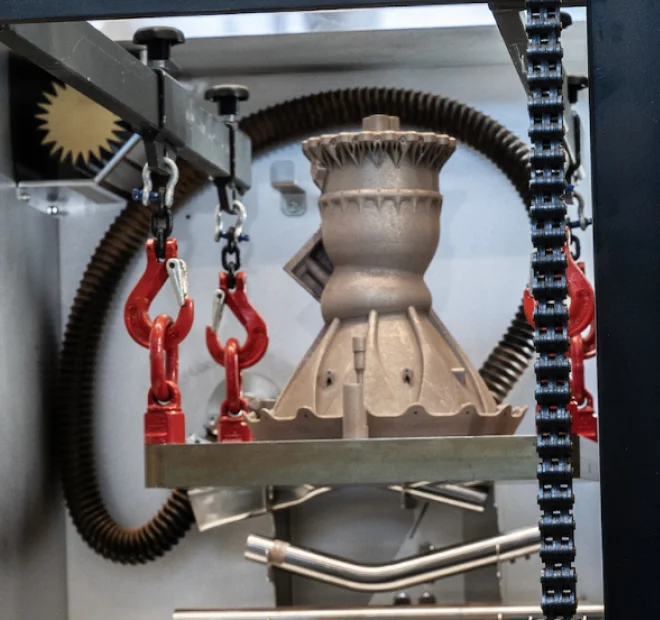

Our additive manufacturing approach isn’t just modern, it’s essential. With AM, we reduce part count, slash development time, and enable on-demand scaling.

test

With fully integrated test infrastructure and rapid iteration cycles, we control our own schedule; that means we test more, learn faster, and deliver flight-ready hardware without the bottlenecks of legacy systems.

SCALE

We design to manufacture– building propulsion systems that scale fast, repeatedly, and affordably to meet the demands of modern conflict.

Additive Manufacturing at Ursa Major

Where Agility Meets Scale

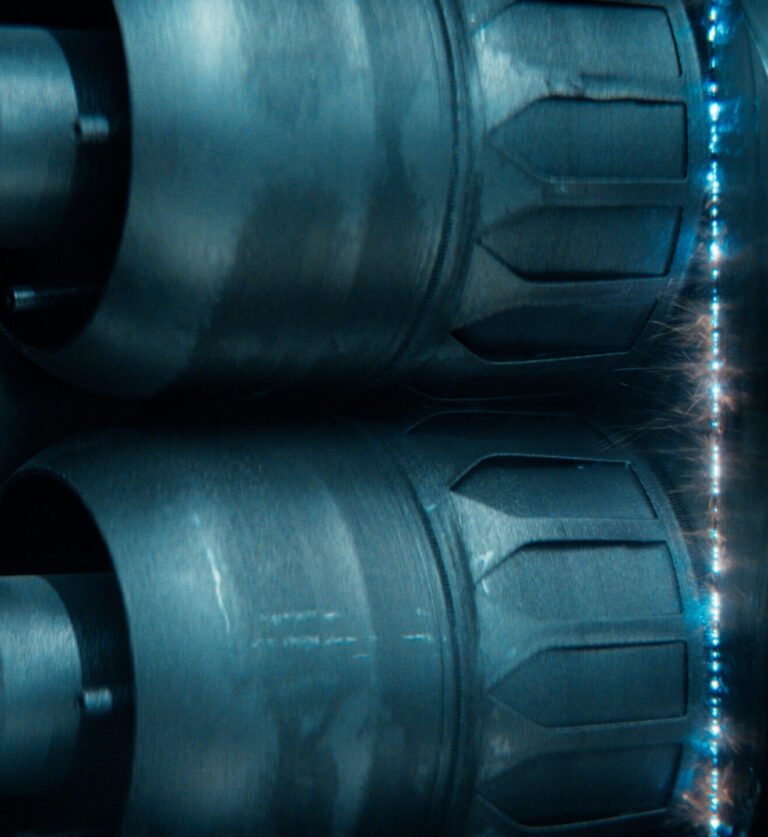

At Ursa Major, additive manufacturing isn’t a trend – it’s a warfighting advantage. We build mission-critical flight hardware, not just prototypes, using advanced AM strategies proven in real-world operations. Our engines and motors are more than 80% 3D printed by mass, with components like thrust chambers, rotating machinery, igniters, and SRM casings fabricated in-house using repeatable, high-performance AM processes.

Strengthening the Defense Industrial Base

America’s defense readiness depends on agile, scalable manufacturing. That’s why we’re not just using additive, we’re redefining how it’s done. With a focus on physics-driven design, open architectures, and flight-proven results, Ursa Major is delivering the systems and the framework to revitalize the U.S. defense industrial base.

Rewriting the Playbook for Qualification

Traditional qualification models weren’t built for AM’s pace. Ursa Major is leading the shift towards process window-based qualification—tying advanced AM file generation to real data from AM Machines, hotfires, and flights to validate our methods. This approach isn’t just more efficient, it’s essential for competing with adversaries who treat AM as a national imperative.